ÄIO product #1: ZymaLipid Complex

The future of sustainable lipids in cosmetics

The world depends heavily on plant-derived oils and butters for cosmetics. Palm oil, coconut oil and tropical butters provide structure, texture and emollience to formulations. But their production is tied to deforestation, biodiversity loss, and climate vulnerability.

At ÄIO, we believe the future of beauty cannot rely on fragile agricultural systems. It must be science-based, scalable and sustainable by design. Here, ZymaLipid Complex is our answer.

What is it?

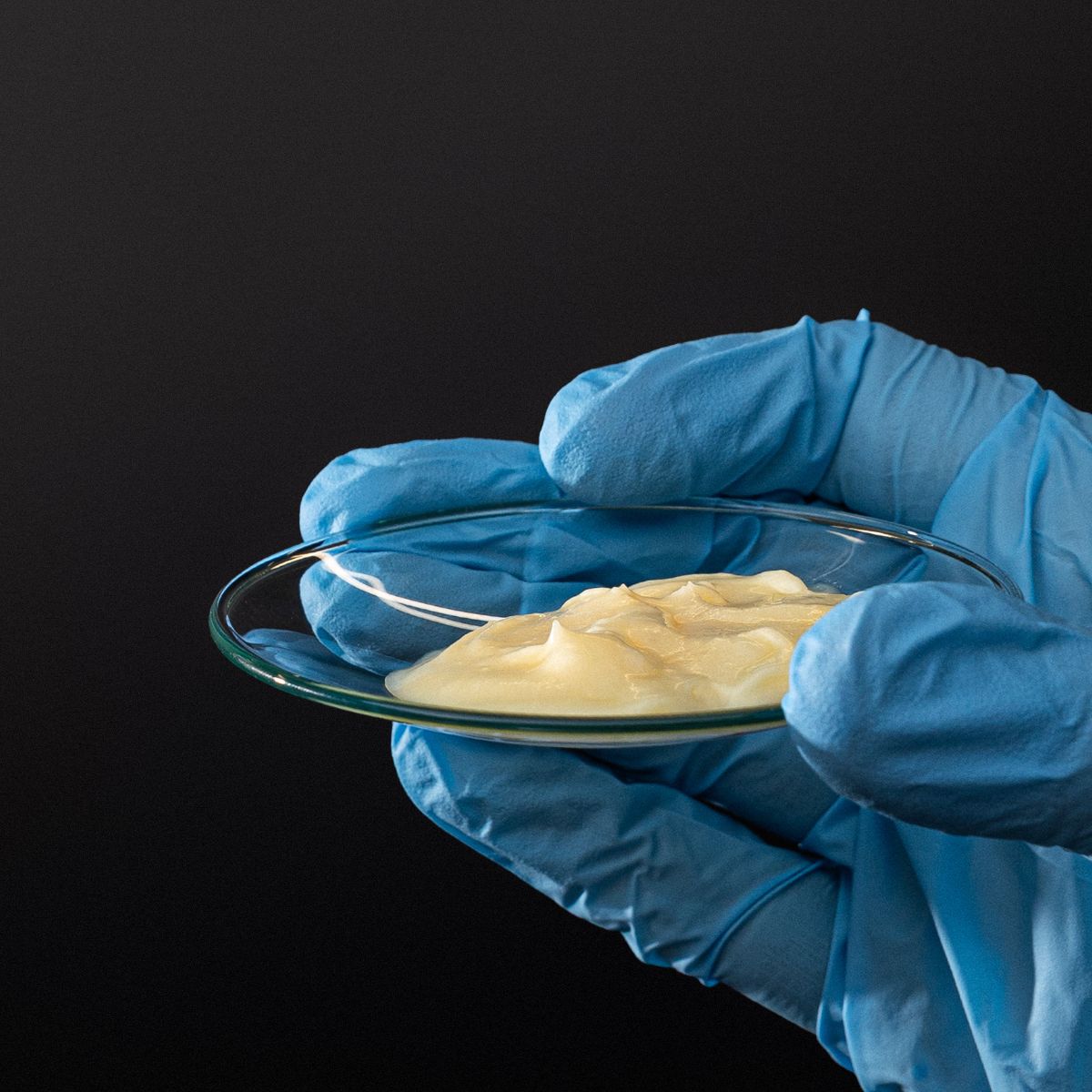

ZymaLipid Complex (INCI: Linoleic/Oleic/Palmitic Acid) is the first commercial fatty acid complex produced through yeast fermentation. It is a high-purity (>99%) blend of oleic, linoleic and palmitic acids, designed to provide both structure and emollience in a single multifunctional ingredient. Unlike conventional oils, ZymaLipid Complex offers a unique semi-solid profile: solid at room temperature, melting at skin temperature.

This creates a luxurious, non-greasy sensory experience while maintaining formulation stability.

Why does the world need it?

Traditional cosmetic lipids are vulnerable to:

- climate change

- seasonal variability

- deforestation-linked supply chains

- quality fluctuations

- regulatory pressure (EUDR and beyond)

As demand for sustainable beauty grows, brands need ingredients that are:

- natural but not climate-threatened

- fully traceable

- stable in quality

- scalable without ecosystem damage

- capable of replacing tropical oils and butters

ZymaLipid Complex enables cosmetic brands to reduce dependency on palm and other tropical oils without compromising performance. It is not just a substitute. It is an upgrade.

How is it produced?

ZymaLipid Complex is produced via yeast fermentation process using locally sourced low-value side streams from agriculture and forestry. Instead of relying on monoculture plantations, we use biotechnology to transform underutilised biomass into high-value lipids. The process has been successfully scaled from lab to pilot scale and to industrial scale, and we are production-ready for cosmetic applications. Batch consistency, quality control, and industrial scalability have been validated.

This means:

- year-round supply

- no seasonal variations

- controlled fatty acid profile

- reduced land and water footprint (74–97% less land, 10x less water compared to agriculture)

Formulation and performance benefits

ZymaLipid Complex was designed with formulators in mind.

Key advantages:

- semi-solid texture (solid at room temperature, melts on contact)

- improved oxidation stability compared to traditional oils and butters

- predictable rheology

- easy emulsification due to lower crystalline rigidity

- reduced hardness of oleogels without impacting viscosity

- film-forming properties

- enhanced penetration

- barrier-supporting fatty acid profile

Fatty acid composition: C16:0 – 16.74%; C18:1 – 55.31%; C18:2 – 16.26%. Balanced saturated/unsaturated profile for structure and softness.

In moisturizer formulations, ZymaLipid Complex reduces the need for multiple oils and butters, simplifying formulations while elevating performance. In lip balms and solid systems, it provides structure without excessive hardness.

Regulatory and market positioning

ZymaLipid Complex is:

- palm-free

- vegan

- natural origin

- readily biodegradable

- sustainably produced

- EUDR compliant

- EcoCert compliant

- European biotechnology origin

For brands, this means strong sustainability storytelling backed by measurable impact. A natural product with up to 10x lower environmental burden compared to conventional plant oils.

Interested to test and buy? Still doubting?

We have successfully scaled production. We are cosmetics-permit ready. We are supplying samples and engaging in commercial partnerships. We are selling! ZymaLipid Complex is not a lab concept. It is an industrial solution.

The beauty industry is entering a new era. One where performance, traceability and sustainability must coexist. ZymaLipid Complex demonstrates that fermentation can replace extractive agriculture in lipid production. Using science, we can end the destructive relationship between consumption and natural degradation and create a future where innovation and nature thrive together.

Let’s talk!